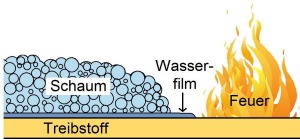

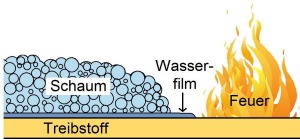

The most

effective extinguishing agents for fuel, apolar solvents and plastics

fires are special extinguishing foams which form a water film on the

surface of the burning liquid (Aqueous Film Forming Foams, AFFF).

(will be translated, soon)

- It allows easier and thus faster gliding of the foam on the

surface of the burning liquid, and thus a faster extinguishing success

and also a larger application radius.

- The increased flowability of the foam on the water film

promotes the self healing of the foam surface during injuries, e.g. by

falling pieces of debris or objects.

- The water film acts as an additional barrier on the burning

material and, as a steam barrier, reduces the flow of combustible gases

into the gaseous firing zone.

- Due to the large heat of evaporation of water, the

spreading film cools the burning liquid and thus lowers its vapor

pressure.

The ability to form such a water film is conferred to currently

available AFFF by poly- or perfluorinated surfactants (PFS), which are

not degraded in nature (persistence), accumulate in the ecosystem

(bioaccumulation) and are suspected of possess toxic effects. A number

of AFFF applications have led to contamination of soil and groundwater.

Partly, he drinking water abstraction had to be suspended in these

regions.

For these

reasons, the use of the previously frequently used surfactant

perfluorooctylsulfonate (PFOS) in AFFF in the EU was banned and PFOS

was replaced by chemically similar substances, so-called fluoroelomers.

However, these substitutes are still fluorinated

and by far also not safe.

It is therefore

imperative to explore new AFFFs which are complete fluorine free,

environmentally friendly and non-toxic, but at the same time have the

necessary properties; i.e. in

particular extremely low surface and interfacial tensions of their

aqueous solutions.

|

(will be translated, soon)

(will be translated, soon)